Description

Application:

Surface treatment:

Rubbing the end-ring and the screen end with a piece of abrasive paper, then cleaning the rubbed surface with acetone or absolute alcohol, drying.

Preparing the glue:

Mix the components a and b in a ratio of 1: 0.5~1homogeneously on a wooden or a rubber plate.

Coating:

Coat the binder evenly on both surfaces between the end-ring and the nicked screen with a scraper, coupling and removing the excessive binder.

Curing:

Curing at 80-120 for 20-30 minutes or 24 hours at interior temperature, or curing at 160-180℃ in a oven with photoemulsion simultaneously.

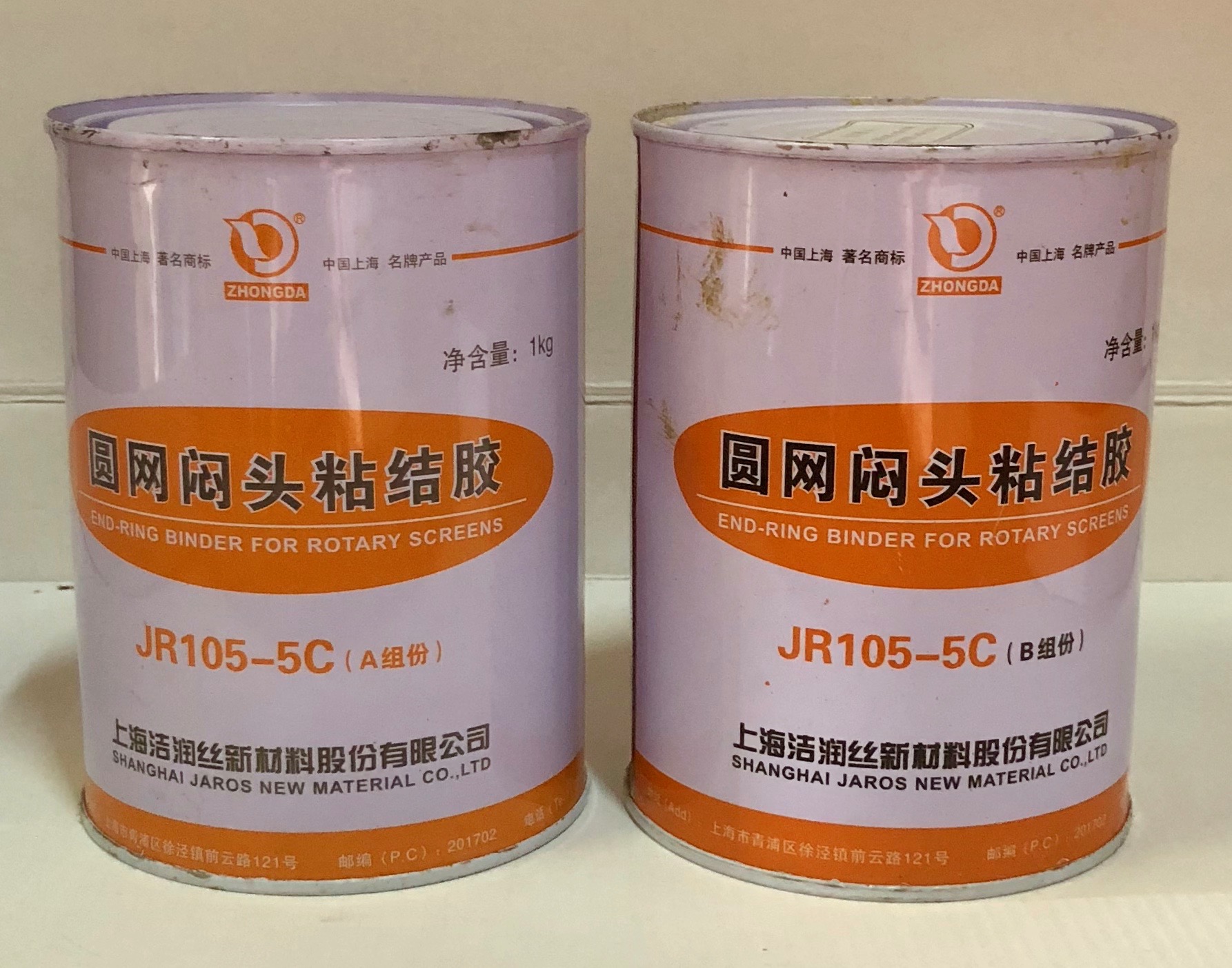

JR105-5CEnd-ring binder for rotary screens (1:1)

|

Package:

Component a: 1kg per iron tank

Component b: 1kg per iron tank, and 10kg every case.

Storage:

One year at 5-35℃(in a sealed and dry place).

- This product belongs to not dangerous article.